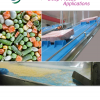

A cherry processing plant in Chile needed some help with an elevator application. The belt needed to lift cherries from a tank of water after washing and allow for dewatering as they were elevated.

While easy enough on the face of it, there were several potential issues that the chosen solution needed to address.

As the main objective of the elevated belt was to move the cherries while dewatering them at the same time, the belt required sufficient openings to allow this dewatering to take place. Conversely, the openings needed to be small enough to avoid cherry stalks becoming trapped in these openings and the fruit becoming damaged due to being trapped in these openings.

The belt being over 1.7m wide and 17m long, tracking of the belt was also one of the issues to be addressed. Since the angle of incline was over 15°, the belt would need to have flights across the width. This would require a strong belt to carry this load meeting all the above-mentioned requirements. The belt also needed to be certified by FDA and USDA as Food Grade for this application.

The solution was Uni MPB 18% PP in blue. This modular belt was the perfect solution, a strong 2" pitch belt allowed for effective dewatering of the cherries and also provided the ability to incorporate staggered flights, which was a necessity for the elevated transporting of the cherries. These staggered flights allowed for the cherries to be transported effectively, while ensuring significant dewatering could take place, which would prove harder in a belt system whose flights weren't staggered. The modular belt does not have tracking issues, once two sprockets on each end are axially locked on the shaft, it runs without any issues for the life of the belt. This belt is also certified by USDA and FDA to be used in food application and allows for direct food contact including meat. The belt is also easy to clean and maintains a high-level of hygiene.

The belt has been in place for one year and is performing extremely well. This is a great example of Viking Conveyor utilising our technical expertise to match the correct belt to a very specific situation.