0800 845 464

0800 845 464

unichains

The brand for plastic modular belts and chains

At Viking Conveyor we offer a comprehensive range of uni plastic modular belts and chains to meet the specific requirements of the food industry.

With growing consumer demand and awareness surrounding eating safe food, the need to produce food with no contaminants is a critical factor in the success of a food brand today. The range of solutions uni-chains offers has been developed to meet the stringent health and safety requirements within a production facility.

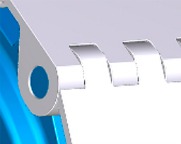

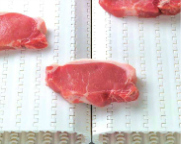

Pop-up flights

Pop-up flight does just what the name says. It pops up at the foot of the conveyor incline to support the food as it moves up the elevator, holding it steady. Then, once the product’s been successfully discharged, the flight pops down again so an automatic scraper can clean up the belt – especially helpful for sticky, clingy food products. So you won’t have to sweep up costly wasted product from the floor as the belt moves on its return path.

Find out more about pop-up flightsuni ULB

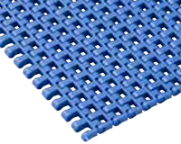

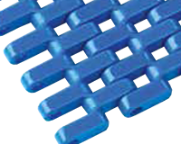

The uni ULB is a game-changer for the industry. There is no other ultra light weight belt like it available on the market.

Destined to be a Food Industry favorite where its hygiene and easy-to-clean features make it a standout, the ULB will be equally appreciated across numerous industries where its exceptional durability and easy maintenance will drive its appeal.

Food Safe, Economical and Environmental

The uni ULB is Food Safe and its remarkably light weight construction contribute to making it a value-for-money solution as well. Suited for light to medium impact applications, it is an economical alternative to heavier and more expensive belts while still getting the job done. What’s more, its unique underside and open-hinge design combined with its light weight make this an incredibly environmental friendly belt by reducing power consumption and water usage needed for cleaning.

The new uni ULB – best and lightest in class.

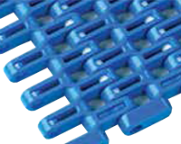

Datasheet uni ULB Cuni M-TTB & uni M-TTB CS

This new generation 0.5 in. pitch belt offers a unique, easy-to-clean surface in combination with self-lubricating POM-D material. The 37% open belt can run over a 19 mm nose bar and is a perfect solution for food processing belts in cooling, freezing, drying or proofing applications.

On top of this the curved surface of the uni M-TTB CS belt offers a reduced contact area of 10% and a smooth transfer. In combination with a 15 tooth sprocket, it forms a circle allowing a scraper against the belt.

Industry Applications:

- Bakery including dough transport, cooling lines, internal transport, metal detectors and packaging lines

- Seafood applications

- Meat and Poultry

- Can making and filling lines

uni CNB

The uni CNB belt is a cleanable belt for conveyance of light duty products in various food applications. The unique hinge and sprocket designs increase the cleanability of the belt. Product supports and side guards are available which limit damage and product loss.

Industry Application

- Meat and Poultry including general conveyance and breading lines

- Fruit and Vegetable including elevators, steam peeler and inspection tables

- Seafood applications including elevators, inspection tables, grading lines, trim lines, glazing lines and cooking lines

uni JCB

uni JCB is the product name for the next generation modular belt designed especially for product handling within the corrugated board Industry.

Surface Profile

The uni JCB belt features a Y surface profile; this surface combines the needs of several functions. The main objective is to improve the non-slip properties of the belt surface whilst at the same time offering a support surface which would not damage or mark the corrugated boards. Thus the Y surface is a careful balance between improving non-slip conditions and non-marking support of corrugated lower sheets.

A tapered or sloping edge profile is retained at both sides of each modular links top surface to ensure no snag points exist when corrugated stacks are pushed sideways on transfer units or stacks have their direction rotated on special conveyor sections. In addition the Y surface plays an important role in improving the mechanical properties of the belts, the extra material in the Y top profile has been placed in-line with the tensile force lines between hinges and serves to increase the overall belt tensile stiffness.

Coloured for safety

Standard construction of all JCB belts for the corrugated industry will incorporate orange links 76mm wide (3 inches) mounted on alternating pitches along both belt edges. This further enhances the safety aspects of the belt.

Datasheet for uni JCBUni QNB

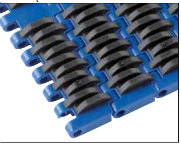

The uni QNB is developed with focus on optimising strength, rigidity and wear life. The belt is unique thanks to its strength and reliability. The chamfered edges provide easy side transfer and eliminate catch points. The uni QNB features a unique locking system for easy maintenance and sprocket engagement for reducing pulsation and increasing load capacity.

The unique Rubber top on the QNB belts eliminate wear and increase the friction properties on incline/decline applications.

We carry the uni QNB product in stock with a closed surface (uni QNB C) and a Rubber Top (uni QNB C Rubber Top). For further information on these products check out the datasheet below.

Industry Applications:

- Bakery applications including plan handling and incline/decline box or pan applications

- Meat or poultry applications including packaging lines and incline box conveyors

- Beverage applications including depalletisers, accumulation tables and incline case conveyors

- Can manufacturing applications including palletiser, mass handling and accumulation tables

- Corrugated applications including downstacker, corrugator take off, transfer car and WIP storage

- Material handling applications including incline applications, palletisers and packaging lines

Datasheet QNB C

uni M-QNB

The uni M-QNB is developed for tight transfer and high-speed conveyors in both food and non-food industries. The 0.5inch pitch, bi-directional belt ensures product stability even in nosebar, long conveyor and high-speed applications thanks to the rounded bottom surface.

The belt offer less vibration and is wear resistant. As with other unichain belts the uni M-QNB has a unique lockpin locking system for easy maintenance and sprocket engagement for reducing pulsation.

Industry applications:

- Bakery applications including dough handling, general conveyance and packaging lines

- Meat applications including tray pack line and metal detectors

- Seafood applications including grading lins weighing lines

- Beverage applications including depalletizer, accumulation tables and acceleration lines

- Can manufacturing applications including depalletiser, accumulation tables and acceleration lines

- Corrugated applications including downstacker, corrugator take off, transfer car and WIP storage

Datasheet uni M-QNB C

uni SNB M2

The SMB M2 range offer less friction and product contact for easy cooking, cooling and freezing of products. The surface is easy to clean so there is reduced dirt and oxide build up. The unique lockpin locking system allows for easy assembly and less downtime.

The SNB M2 features surface opening of 20%, 34% and 50%. The SNB 20% allows for gentle transport of sensitive products and an open surface for airflow or drainage. The unis SNB M2 34% is unique in dry accumulation applications.

The belt increases performance in the following industries/applications:

- Meat applications including microwaves, cooling and freezing lines

- Fruit and vegetable applications including de-watering lines, cooling and freezing lines

- Pasta applications including blanchers, pasteurisers and cooling lines

- Beverage applications including accumulating tables, infeed to packaging, pasteurisers and palletizers

- Can manufacturing applications including accumulation tables, mass handling and palletizers.

uni MPB

The uni MPB belt is the most cleanable, 2 in. pitch, straight running plastic modular belt in the world and the belt holds the valid NSF/USDA approvals. The belt is used in various food applications and offers various styles from closed and open surfaces to roller or rubber top.

The belt is available with different openings to optimise drainage and airflow. The openings include 20%, 22% and closed. We also range the closed rubber top option (uni MPB C Rubber Top).

Industry Applications:

- Meat including deboning lines, fat/trim lines, cutting lines, offal lines, evisceration lines, packaging lines and elevator/incline conveyors

- Poultry including cage dumper lines, deboning lines, fat/trim lines, offal lines, grading lines, packaging lines and elevator/incline conveyors

- Fruit and Vegetable including elevators, steam peeler lines, inspection tables, blanchers and packaging lines

- Seafood including bulk feeder, elevators, inspection tables, grading lines, glazing lines, cooling and freezing lines

- Snack food including fryer discharge and incline applications

Datasheet uni MBP 20% Datasheet uni MPB 22% Datasheet uni MPB C

uni S-MPB

The uni MPB belt is the most cleanable, 1 in. pitch, straight running plastic modular belt in the world and the belt holds the valid NSF/USDA approvals. The belt is used in various food applications and offers various styles from closed and open surfaces to roller or rubber top.

it is suitable for the same applications as the uni MPB.

Datasheet uni S MPB C Datasheet uni S MPB 22% CSuni Flex ASB

This new generation of 1 inch radius belts, with a flat or curved surface, offers a unique patent design. It is a very strong radius belt that is easier to clean and features POM-D material.

The uni Flex ASB is a proven belt in spiral applications. The increased lateral stability allows for fewer support strips than normal, and the bevelled edges facilitate side way loading. Furthermore, the curved surface of the uni Flex ASB CS belt offers a reduced contact area of 10% and a smooth transfer.

We carry the uni Flex ASB R2.2 and uni Flex ASB R2.2 Rubber top instock. For further information on these products check out the datasheet below.

Industry Applications:

- Baking including dough, transport, cooling lines, internal transport, metal detectors and packaging lines

- Seafood including tray-packing lines

- Meat and Poultry including packing lines

- Spiral applications as proofing and freezing of croissants, cooling and resting

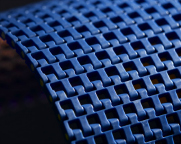

uni Flex SNB

uni Flex SNB is a strong and tight radius flexing belt. It features a 1inch pitch and is created to optimise throughput in high volume operations with space limitations. The belt has unique strength and side flexing characteristics and is used in many different applications.

uni Flex SNB has a 180 degree high speed side flexing ability; high temperature and wear resistance; unique locking system; unique radius top surface for minimum product contact and less friction; and reinforced stainless links for higher strength, speed or load.

We hold the uni Flex SNB CR 1.6 in stock (image above)

Industry application:

- Meat and Poultry applications including tray pack conveyors, box/tote handling, freezers infeed/outfeed, low tension spirals and other side flexing applications

- Fruit and vegetable applications including filling lines, canning lines and incline/declining applications

- Bakery applications including cooling lines, pan handling, proofers and oven infeed and takeaway

- Beverage applications including case conveyors, shrink tunnels and incline/decline applications

- Can manufacturing applications including mass handling, transfer conveyors and palletisers infeed conveyors

Datasheet uni SNB CR R1.6