0800 845 464

0800 845 464

Rubber Lining

Protecting your plant and infrastructure from abrasion, chemicals, acid/alkali and heat will extend the lifetime of your asset; reduce maintenance and any downtime from damage.

At Viking Conveyor we have extensive technical expertise to ensure that the right rubber lining or lagging solution is applied to your plant and infrastructure. Each project has unique requirements and with over 40 years’ experience in the industry, we have the knowledge and practical expertise to ensure your plant and infrastructure will be well protected.

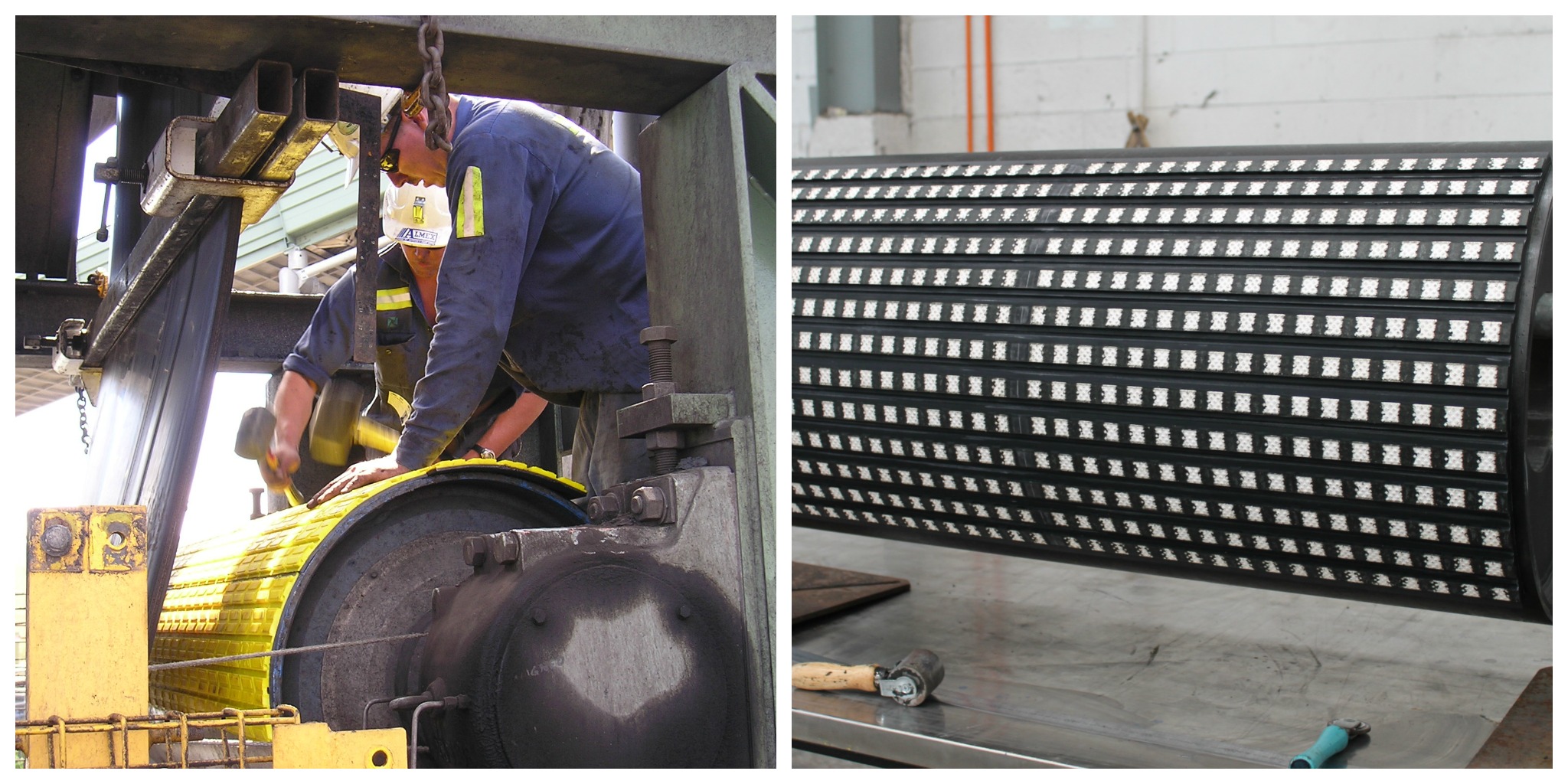

Our range of rubber linings encompasses applications where protection against abrasion, chemicals, acid/alkali, heat and noise are required. We offer both the internal lining of chutes, vessels and pipes as well as the lagging of drums, where protective lining is applied to the exterior of a drum.

Lagging is designed to provide a longer service life to the pulley and belt by increasing the coefficient of friction between the lagging and the belt.

Lining Benefits

- Excellent resistance to wet abrasion

- Very high resilience

- Remarkable cut and tear resistance

- Low permanent set

- Resistant to a wide range of chemicals

- Excellent electrical resistance

- Sound-absorption and vibration dampening properties

Lagging benefits

- Reduces slippage between belt and pulley

- Improves and stabilises coefficient of friction

- Evacuation of moisture and dirt

- Protects the pulley against wear and corrosion

- Prevents material build-up

- Positive influence on belt tracking

Our Experience

Our rubber lining experience includes protecting chutes, pipes, tanks, vessels and drum lagging. Check out the images below to see the type of work we undertake.

Hot or cold bonding?

There are two rubber lining processes:

Cold bonding

Adhesive is used to bond wear resistant rubber sheet to steel work. It is a cost effective and fast process.

Hot bonding

Lining of vessels and pipes in raw rubber which is subsequently cured in an Autoclave or using open steam curing (where the vessel acts as the autoclave). Vulcanising the raw rubber produces a seamless lining eliminating adhesive joins associated with cold bonding.

Hot Bonding is recommended for chemical reaction vessels and abrasive slurry handling applications. It has superior durability when compared to cold bonding.

Big autoclave for hot bonding

We have one of the largest autoclaves in this part of the world, ready to protect your plant and infrastructure!

It is not just about the rubber

The selection of the rubber type, the formulation of the mix and the thickness of the lining is determined by the actual construction of the vessel, pipe, chute or drum and the actual chemical, thermal and mechanical conditions the lining will be exposed too.

A suitably formulated rubber can withstand extremes of temperature, acid/alkai and also abrasion media. For example:

- Nitrile Rubber (N.B.R) provides good resistance to oils, greases, petroleum, hydrocarbons, non polar solvents and dilute acids

- Bromobutly (B.I.I.R) provides good resistance to acids and alkali over a range of PH at elevated temperatures.

Even the best will need replacement

Even the best rubber linings and laggings will eventually need repair or replacing. At Viking will we can supply our service either on a routine or emergency basis. This service can be on site or in our Auckland workshop.

Rubber Lining Products

Our protective rubber lining and sheeting products provide the following protection for your products:

- High chemical resistance (chemical damage prevention)

- Protection from Oil and Fuel damage

- Impact protection

- Abrasion protection

- Corrosion protection/resistance

Lagging Products

Our rubber lagging solutions range from a lighter weight resistant finish to a robust, heavy duty resistance.

Check out our Rubber Lagging ProductsTechnical Expertise

The correct selection of the most economic protective rubber lining calls for a detailed knowledge of the process which could adversely affect the durability and integrity of the protective lining. Our Fabrication Technical Manager is a Rubber Chemist with over 30 years experience in the Industry both in New Zealand and abroad. Terry has the experience to ensure that the correct rubber, bonding system and fabrication processes are specified to protect the plant and infrastructure so that its optimal life is achieved.

Click here to get in touch with Terry