0800 845 464

0800 845 464

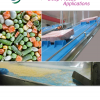

Primary Produce

Keeping it tasty

New Zealand’s economy is heavy dependent on agriculture which includes primary produce. At Viking we are passionate about helping meat and poultry companies move their product from arrival through to the final product.

Our experience and product range is able to support the multiple applications that occur within a processing facility.

Food Safety is the only choice

With growing consumer demand and awareness surrounding eating safe food, the need to produce food with no contaminants is a critical factor in the success of a food brand today.

We can assist in controlling your identified contamination hazards through specifying, installing and maintaining the right conveyor systems to cope with the specific food safety requirements.

Protecting your brand

If your food is safe you can be confident that your business will be safe.

Choosing the right Conveyor System

At Viking Conveyor we will work with you to establish the specific requirements of your conveyor belt system taking into account key questions such as:

- What products are processed on the belt?

- What process is the belt involved in; heating, cooling, washing, cutting, deboning, cooking?

- How can the conveyor belt assist with your HACCP?

- How will the belt be physically arranged – is there an incline or decline?

- What are your cleaning requirements?

- What are your production optimisation targets?

Characteristics of the belt

There is such a diverse range of conveyor belts available for the processing of primary produce. At Viking Conveyor we have access to a comprehensive range of belts. Our service includes taking the time to understanding your operation and making sure the characteristics of the belt will be suitable.

Key characteristics to consider are:

- How easy is the belt to clean?

- Is it easy to maintain?

- What is it impact resistance?

- Does it require side flexing?

- Does it need to be non-stick and reduce friction?

- What is the belt cutting resistance?

- What tensile strength is required?

- What belt profile /surface is required e.g. smooth or chain?

- Which belt will lessen damage and product loss?

If you need some advice don’t hesitate to give us a call on 0800 845 464

Product range

Our product range includes leading products available from uni chains and Volta. Both have an extensive range of products with varying characteristics to demands of processing primary produce.

Our product range includes solutions for the following applications:

- Offal Conveyors

- Cutting Lines

- Deboning Lines

- General Conveyance /Straight Lines

- General Conveyance /Side Flexing Lines

- Elevator / Inclines

- Shrink wrap

- Box Handling

- Metal Detectors

- Packing Lines

We can present their options to you. Give us a call on 0800 845 464.

Technical Expertise

Each part of processing food may well require a different conveyor belt system. Our team has the technical expertise to look at your processing requirements and work with you to find the right conveyor solution for your site – whether it’s on handling raw materials, part of the cooking process or the packaging line.

Our Experience

Food Safety Catalogue Volta Product Range UniChain Product Range Ammeraal Product Range Ammeraal Meat Industry Brochure

Need help in finding the right product or solution for your project or site?

For non-sales related enquiries please contact us on +64 9 272 9796