0800 845 464

0800 845 464

Industrial Belting

Industrial Belts

At Viking Conveyor we offer a range of industrial belts that are designed to handle the conditions in quarries and mines. Check out our range below.

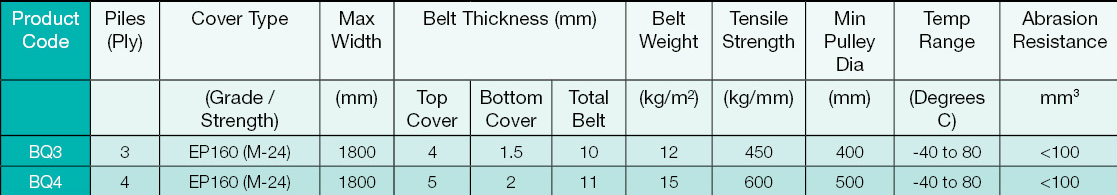

Quarrior

Quarrior is a quality M Grade Belt with high gouge and tear resistance combined with high abrasion resistance. It is an excellent utility conveyor belt designed to handle sharp rock while maintaining good abrasion resistance to fines.

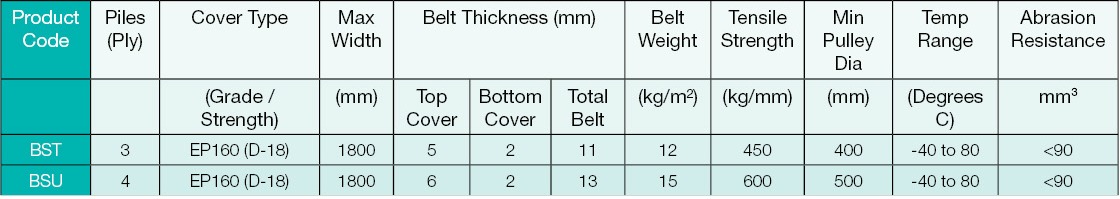

Tuffply

Tuffply is a high quality D grade Super Abrasion Resistant conveyor belt which performs best in applications handling abrasive fines such as coals, fertiliser, lime, sand, shingle and palm kernel. To further extend its wear, Tuffply has an additional 1mm of top cover.

Tuffply Primary

This is an M Grade Primary Belt with Breaker Ply which has excellent gouge, tear and abrasion resistance.

Viking

This is a general purpose, economical solution. It is an N Grade Belt and suitable for general purpose.

Specialised Belts

The belts below are what we consider to be specialised belts that have strong features and benefits to match the application.

Baler Belt

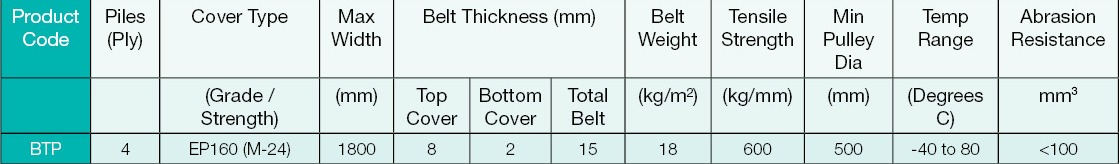

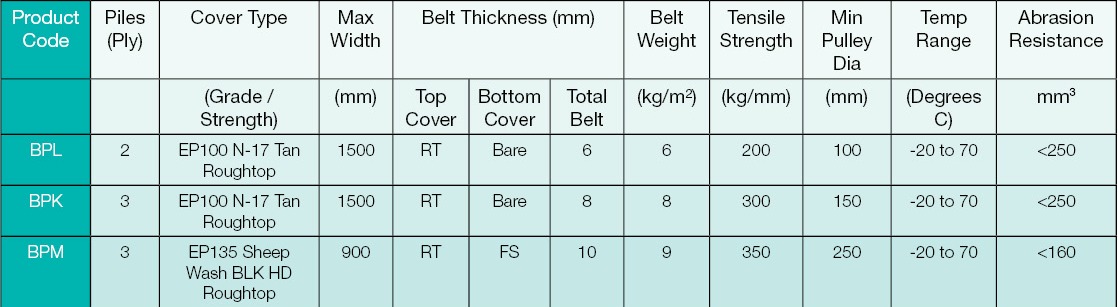

Tough, high strength product capable of handling the small pulley diameters encountered on round baler machines.

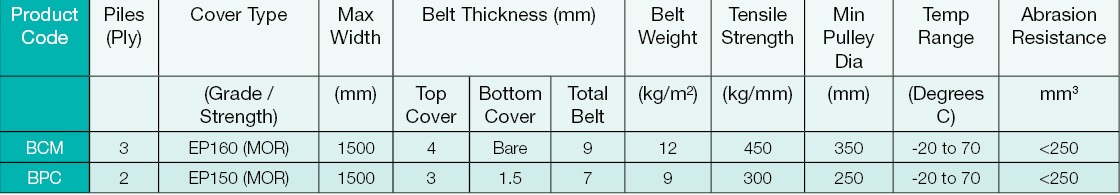

TimberMate - Sap and Wear Resistant Timber Belt

The workhorse of the timber industry TimberMate rubber conveyor belt has high tensile strength and extreme resistance to degradation from aggressive alpha and beta Pinene present in Radiata pine sap. It is designed for handling bulk products including wood chips and wood scrap on troughed conveyors.

Benefits

- Superior to MOR and SOR belts

- Nitrile rubber covers protect from attack by wood sap

- The Nitrile rubber will carry wood chip up a greater incline

- The 3ply heavy duty carcass gives strength for long run conveyors

TimberSlide

TimberSlide is a long lasting Timber rubber conveyor belt which slides with minimal friction, designed for handling timber on a flat steel/timber deck at speed.

Benefits

- The heavy Nitrile rubber cover combines good impact and abrasion resistance with a high resistance to wood sap attack

- The high strength 3ply EP160 carcass gives a high working tensile strength for long conveyors

- Cushion rubber between the second and third plies gives additional impact resistance when handling heavier timber

- The bottom of the belt is a very low friction bare fabric that reduces the power required to drive the conveyor and allows the belt to run at high speed

- Slider bed conveyor construction is simple and economical compared to the moving components required on troughed conveyors.

Viking MOR

MOR (Moderate Oil Resistant) is a economical alternative. It is a rubber conveyor belt designed for applications with intermittent or moderate oil exposure with moderate wear performance, such as in the Timber Industry.

Profiled Belts

These belts are designed to move products while they are on the incline of the conveyor system.

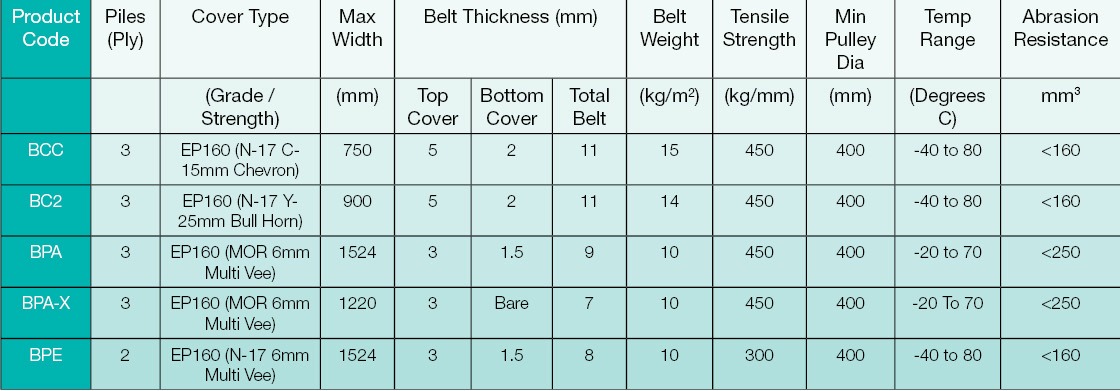

Chevron/Cleatface

Chevron/Cleatface belt is a moderately wear resistant V cleated belt designed for conveying materials that are to move up steeper inclines (generally over 15 degrees).

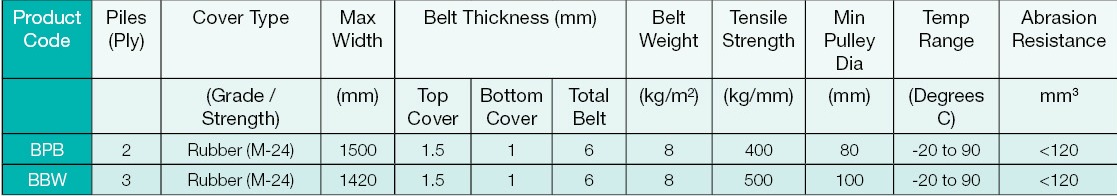

Rubber Rough Top

Rubber Rough Top belts are primarily used on packaged goods on incline conveyors.

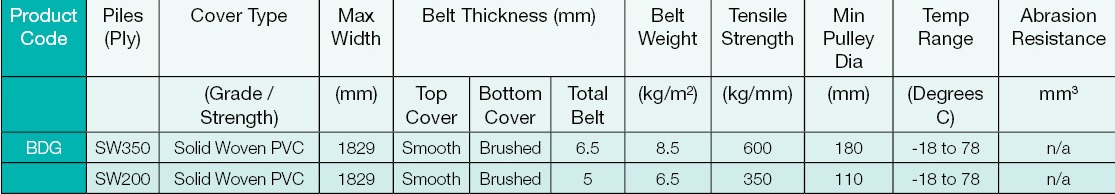

Solid Woven

High tear resistant belts used for sorting, material handling and transfer.

Yokohama

The key to rationalisation of a conveyor system is to choose the right belt for the task. Yokohama Rubber conveyor belts are available in a broad range of specifications relating to cover compound, carcass and structure. The belts are at a premium level and tailored-made to meet the specific requirements of a site. They offer a unique solution.

The Yokohama Product Range includes:

| Kind of Carcass | |

| Steel Cord Conveyor Belts | |

| Multilayer Fabric Conveyor Belts | |

| Aramid Conveyor Belts | |

| Unicon Belts | |

| Rock Conveyor Belts "PROTEX" | |

| YOKOHAMA MJ Type Conveyor Belts | |

|

Special Application |

|

| Bucket Elevator Belts | |

| Chevron-Patterned Conveyor Belts | |

| Rough Top Conveyor Belts | |

| Rip Stop Conveyor Belts | |

| Seal Belts | |

Contact us today to discuss the right Yokohama solution for your site.

Product Range

Viking Conveyor Industrial Catalogue Quarry and Mining Brochure Abrasion Resistant and Pulley Solutions Industrial Conveyor Accessories

Need help in finding the right product or solution for your project or site?

For non-sales related enquiries please contact us on +64 9 272 9796