0800 845 464

0800 845 464

Positive Drive

SuperDrive™

SuperDrive™ conveyor belting reduces sanitation time (less changeover time between shifts and more production time), reduces maintenance, reduces water and chemical expenditures and reduces electricity consumption. It lowers bacteria counts for a cleaner, healthier product with improved product shelf life.

Volta SuperDrive in Action on YouTube

Mechanical Benefits

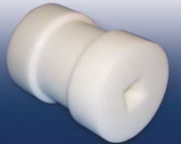

Volta Belting’s SuperDrive™ system presents a homogeneous Thermoplastic Elastomer (TPE) positive drive conveyor belt with two parallel rows of extruded teeth on the underside of the belting material. The teeth engage in a toothed drive sprocket that drives the belt with little or no pretensioning to prevent off-tracking.

- Minimal pretension reduces elongation

- Reduces noise level to a minimum

- Lightweight belting cuts back on motor and energy usage

- Easy to install

- Strong base for heat-welded fabrications

- Long operating life

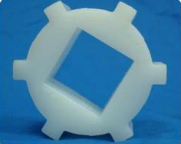

SuperDrive™ Sprockets

SuperDrive™ Tail Pulley (200mm) SuperDrive™ Drive Pulley (200mm)

DualDrive

Volta Belting’s DualDrive positive drive belts lower the cost of ownership due reduced consumption of water and chemicals, reduced maintenance and sanitation costs and reduced downtime. Lower bacteria counts deliver a significantly more hygienic product with improved shelf life.

Mechanical Benefits

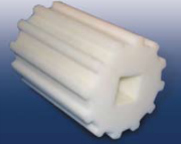

The DualDrive conveyor belt is a positive drive conveyor belt with a series of teeth extruded at a pitch of 50mm (2”) across the entire width of the underside. The teeth engage in a toothed drive sprocket that drives the conveyor belt with little or no pretensioning. DualDrive belts replace 2” pitch modular belts with minimal retrofitting.

- No seams, finger splicing, pins and hinges

- Extruded in 30m or 60m (100ft or 200ft) lengths

Dual Drive Sprocket (38mm)

DualDrive SP (Small Pulley)

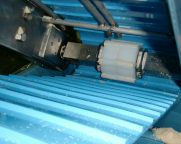

Ideal for small pulley applications and can be applied to existing lines with convenient minimal retrofit.

What makes DualDrive SP so special?

- It runs on small drive & tail pulleys: 50 mm (8 teeth)

- Tight transfer of goods reduces product wastage

- Lighter conveyor construction, saving drive motor energy costs

- Positive drive mechanism prevents slippage

- Fully extruded drive surface has the combined option of positive drive and/or built in cleats

- Can be made endless with DD SP Lace for easy removal for cleaning or maintenance purposes

Low load and high load applications

There are 2 series of pulleys that can be used with this belt. One is specifically suitable for using in high load (HL) applications and the other is designed for use in low load (LL) applications.

It is essential that the correct pulley type is chosen in relation to the belts pulling force. The use of incorrect pulleys can cause a problem of disengaging.

DualDrive SP Sprockets

38mm for High load; 25.4mm for Low load

Product Range

Need help in finding the right product or solution for your project or site?

For non-sales related enquiries please contact us on +64 9 272 9796