Challenge

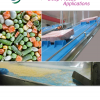

Leader Products manufactures quality frozen and convenience food. Their product ranges includes yummy items such as burgers, meatballs, nuggets and ribs.

One of their production lines included a modular belt which featured cavities. Food cavities in the belt made cleaning difficult to the rigorous demands of preoperational inspections which could cause the need of re-cleaning and delaying production starts. To ensure that hygiene was perfect the first time, Leader decided it was time to look for an alternative for their modular belt.

Due to their long standing history in the food industry, Viking Conveyor was approached to provide their expertise and advice on best possible food belt for Leader Products and its processing requirements.

Solution

The following steps were taken, with Leader Products, to ensure the best possible conveyor belt systems were considered in line with Leader Products requirements:

Site visit

Viking Conveyor visited the processing facility to review the current belt and discuss with Leader Products what they were looking for from their new belt.

Alternative solutions proposed

Two alternative solutions were proposed, with one in particular considered the best solution as it met all of Leader Products criteria. The Volta SuperDrive was discussed with Leader Products Engineering Manager and QA Manager to ensure all parties were comfortable that the Volta SuperDrive Conveyor Belt would meet their specific requirements from a mechanical and food safety perspective.

The Volta SuperDrive was able to meet Leader Products requirements in the following key areas:

- Food Safety - high food standards for both the local and international markets

- Smooth non-porous surface, which can repel bacteria that cause spoilage and harbour bad odours

- Easy to clean - hygiene levels extremely important to ensure that food is produced safely for the customer. With the additional benefit of efficient cleaning on site requiring low water usage and labour time

- Easy to retrofit - easy to replace so that the whole mechanics of the belt would not have to be replaced in the future

- Homogeneous through and through - Volta is made from materials that will not fray or come apart at corners or edges

- Reliable - positive drive and consistent tracking to reduce any product loss and damage to the belt

Result

The Volta SuperDrive belt is up and running in the Leader processing plant, delivering on a high standard of food safety and reliability.