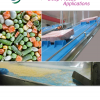

Conveyor belts come in to regular contact with food as part of their processing and a belt is an important component in producing a product that is safe for consumers to eat and drink.

So how do you ensure that the food you are providing is safe and contaminant free? At Viking Conveyor we can assist in controlling your identified contamination hazards through specifying, installing and maintaining the right conveyor systems to cope with your specific food safety requirements.

With a number of outstanding brands as part of our offering and our unrivalled conveying knowledge, it's hard to not choose Viking Conveyor to meet the conveyor belt requirements of your site.

Ammeraal

Ammeraal is regarded as a world leader in process and conveyor belting. Being renowned for innovative design and manufacture of a large range of belting systems, Ammeraal provide solutions to a number of industries, including Food Processing.

A key focus for Ammeraal is providing a variety of belting solutions that are safe and clean. Ammeraal have many food safety features that are incorporated in their various belt solutions. Across their range, Ammeraal belts are durable and easy to clean; have a contamination safeguard; assist in lowering bacteria counts; have hygienic easy cleaning inclines and are easy, fast and effective to clean.

Uni-Chains

Viking Conveyor offers a comprehensive range of uni plastic modular belts and chains to meet the specific requirements of the food industry. The range of solutions Uni-Chains offers has been developed to meet the stringent health and safety requirements within a production facility (Viking Conveyor are New Zealand's only authorised distributor of Uni-Chains products). One such Uni-Chains product is the Uni-Flex ASB. It has POM-D material which incorporates a self-lubricating component, meaning the non-stick feature of the belt is enhanced. This POM-D material, along with the improved hygienic design of the hinges, also allows for Uni-Flex ASB to be easily cleaned.

Volta

Volta belts meet the toughest international standards for food contact materials. Their food approved flat belts will significantly increase the hygiene level of your entire production line and reduction in bacteria build-up will be seen. The belt's surface is smooth, with no crevices, which if present, could trap harmful bacteria.

Fraying of the belt edges can cause fragments or contamination in the food products. Made from TPE, the Volta homogenous belt will not fray or come apart at the corners or edges. The belt is also constructed without pins or joins. And finally the fully extruded, smooth Volta belts allow substantial savings in maintenance, downtime and water.

While these products provide for outstanding food safety already, Volta's Metal Detectable Belts are stepping things up again. Friable modular belts are used extensively and there are concerns over plastic contaminants infiltrating the food flow. While Volta's belting solutions are not disposed to this type of fragmentation, there is increasing desire from food processors for metal detectable plastic belts. Therefore one has been developed to provide the insurance policy that has been sought.

So how could Viking Conveyor's solutions help your site?

Well, each site and production facility has its own unique requirements, therefore we recommend that the best way to approach things is to meet and discuss your site requirements. From there we can use our technical expertise, industry experience and extensive product range to suggest the best possible, personalised solutions for your site.