0800 845 464

0800 845 464

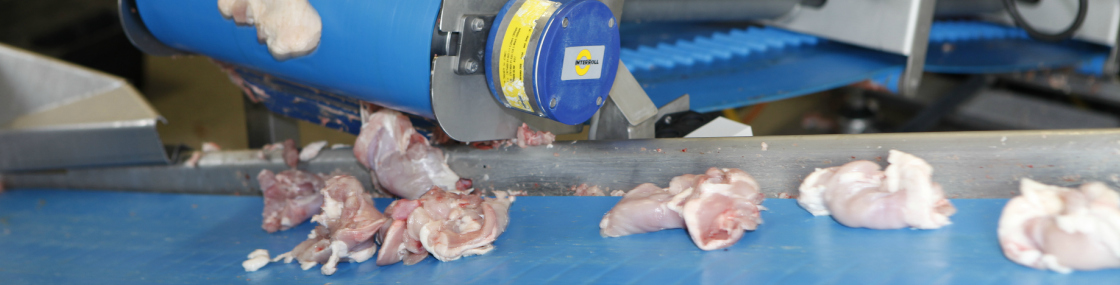

Bacterial Resistant Belt for Tegel Chicken

Challenge

The Tegel Drury Chicken Processing Facility was in dire need of a new belt on one of their lines. The belt was required to elevate trade waste (egg remnants and empty egg shells) from their take-off area to a maceration system, and was in use approximately 6-8 hours per day.

The existing PVC conveyor belt with sidewalls and cleats, was beginning to fail; clearly a better solution was required. Issues identified for the existing system included being difficult and time consuming to clean, heavy discolouration of the belt and top cover degradation. In addition the belt emitted a foul odour, making working conditions very uncomfortable.

The carcass of the belt was saturated in trade waste and cleaning solutions, both of which had seeped in to the plies of the belt. Most concerning of all, the belt was displaying high bacterial counts; an obvious issue in an industry so concerned with and focused on health and hygiene.

Solution

To resolve these issues, Tegel approached Viking Conveyor, who recommended a homogenous conveyor belt with high-frequency welded sidewalls and cleats, giving superior bond strength and longterm durability. The customer specifications called for 40mm sidewalls and cleats and fitted with a stainless steel fastener for quick and easy removal.

The homogenous Volta FMB 3mm series was chosen for a number of reasons. Volta provided a solution that was free of any fabric and easy to clean, with no saturation of the conveyor in product and chemicals, resulting in significant savings from quicker cleaning and lower sanitising costs.

The extra clean-ability would also mean that there would be no discolouration of the conveyor, and the cleats and sidewalls were secure. After installation, a reduction in odour was noted and, most importantly, a significantly reduced bacteria count. This provided assurance that a healthy, hygienic solution had been delivered.

As well as resolving all the initial issues, Volta also provided other benefits:

- Projected longer service life due to cut and abrasion resistant surfaces.

- Cost-savings from reduced cleaning time together with a reduction in water and chemical usage.

- The non-absorbent nature of the belt results in lower bacteria counts and increased hygiene levels.

Result

Tegel received a solution they could rely on to achieve the necessary goals with Volta. Tegel’s Hatchery Production Manager, Mr Warwick Maxwell, can already see the benefits of the new Volta belt: “The belt has performed very well. It is far easier to clean and manage than the previous system was. I am very impressed with the service offered and the product installed.”

Download the full case study in PDF